Innovative Topene™ RB Blown Film for Bags

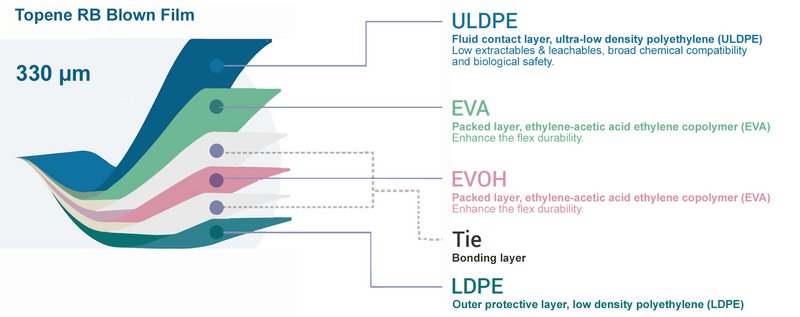

The innovative Topene™ RB blown film designed for biological processes is composed of ULDPE (ultra-low-density polyethylene), EVA (ethylene-acetic acid ethylene copolymer), EVOH (ethylene-vinyl alcohol copolymer) and LDPE (low density polyethylene). The ULDPE layer with low extractability, low precipitation, good chemical compatibility and biological safety is used as the liquid contact layer. The EVA layer has good resistance to flexural cracking and the EVOH layer minimizes gas diffusion of the film. The outer LDPE layer provides strong puncture resistance, strength and excellent thermal stability.

The Topene™ RB film has an ultra clean inner surface, good environmental stress resistance, tear resistance, rubbing resistance, tensile resistance, chemical stability and biological safety.

Topene™ RB Blown Film - Layers

Topene™ RB film is 11-layer co-extruded film and only the functional layers are shown in the schematic.

Features

- Superior mechanical strength

- Excellent flex durability

- Low extractables and leachables

- Superior cleanliness

Specification

Appearance Parameters | Value (After gamma sterilization > 25 kGy) | Procedure |

| Thickness | 0.326 mm | GB/T 6672 |

| Haze | 6.0 % | ASTM D1003 |

| Specular Gloss | 96.1 GU | ASTM D2457 |

| Colour | SCI: L 93.72, a -0.12, b 2.34 | ASTM D6290 |

| Light Transmittance | 90.7 % | ASTM D1003 |

| Luminous Transmittance | 75.06 % | GB/T 2680 |

| Diffuse Reflectance | 3.78 % | GB/T 2680 |

| Transmittance | 77.6 % | ASTM D1746 |

Physical Parameters | Value (After gamma sterilization > 25 kGy) | Procedure |

| Density | 0.936 g/cm² | ASTM D792 |

| Hardness | A/93/1 | ASTM D2240 |

| Tensile-Strength | Transverse 159 Longitudinal 136, bar | ISO 527-3 |

| Modulus of Elasticity | Transverse 2260 Longitudinal 2300, bar | ASTM D882 |

| 2% Secant Modulus | Transverse 2000 Longitudinal 2010, bar | ASTM D882 |

| Tear Strength | Transverse 22.6 Lengthways 22.4, N | ASTM D1004 |

| Puncture Resistance | Inner face 36.0 Outer face 39.0, N | ASTM F1306 |

| Dart Impact | > 975 g | ASTM D1709 Method B |

| Glass Transition Temperature | - 18 °C | ASTM D3418 |

Barrier Performance | Value (After gamma sterilization > 25 kGy) | Procedure |

| Water Vapor Transmission Rate | 0.489 g/(m²·day), (23 °C, 100% RH) | ASTM F1249 |

| Oxygen Permeability | 0.296 cm³/(m²·day·bar) | ASTM D1434 |

| Carbon Dioxide Permeability | 0.318 cm³/(m²·day·bar) | ASTM D1434 |

Regulatory Compliance | Value (After gamma sterilization > 25 kGy) | Procedure |

| Particulate Matter | Particulate matter in the product eluent meets the requirements in USP <788> for large volume parenterals | USP <788> |

| Bacterial Endotoxin | Aqueous extraction contains < 0.25 EU/ml as determined by Amebocyte Lysate, USP <85> | USP <85> |

Typical Applications

The Topene™ RB film has performed a comprehensive validation, which has low extractable and precipitate levels and good cell compatibility, and there is no potential risk of introducing impurities into the biological process. Topene™ RB film can be applied to the whole biopharmaceutical process such as upstream cell culture, configuration and storage of buffer and media, preparation and filling.