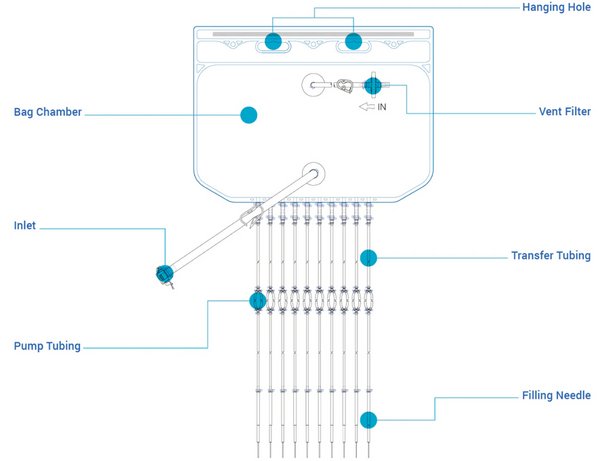

Final Filling Assemblies

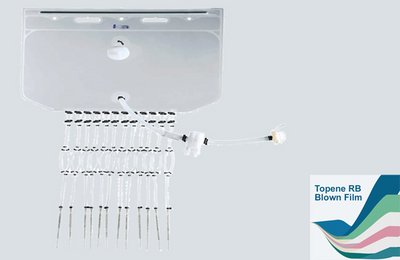

Masterfilter Single-Use Final Filling Assemblies is a pre-assembled, pre-sterilized aseptic transfer production unit, including liquid storage bags, sterile filtration, single-use filling bags, filling tubing, and filling needles. Single-use filling assemblies are designed for the aseptic processing and transfer of biopharmaceutical fluids. They represent a critical advancement in modern drug manufacturing, replacing traditional stainless-steel vessels to enhance efficiency, safety, and flexibility.

Features

- Innovative Topene™ RB blown film, reducing the contamination of particles

- Sterilized by 25-45 kGy gamma irradiation

- Designed with boat ports for ultra-low residual liquid

- Validation services are available for extractables and leachables, chemical compatibility

- Customized assemblies

Quality Assurance

- ISO 9001: 2015 quality management system

- Filling bags are manufactured exclusively in a dedicated ISO 4.8 cleanroom. Fittings entering through transfer window. Personnel entering through air shower room.

- 100% bag integrity test

- ADCF raw material meets the requirement of FDA 21 CFR 177-182 indirect food additives

- Meets the requirement of ISO 11137 sterilization validation

- Meets the requirement of USP <87> in Vitro Biological Reactivity Test

- Meets the requirement of USP <88> Biological Reactivity Test, in Vivo for Class VI plastics

- Aqueous extraction contains < 0.25 EU/ml as determined by Limulus Amebocyte Lysate (LAL), USP <85>

Applications

- Antibodies

- Vaccine

- Gene therapy

- Etc.

Configuration Options