Single-Use Systems (Standard and Customized Solutions)

Single-Use System (SUS) is a process solution that offers advantages such as lower upfront costs, no cleaning requirements, and accelerated research and production progress compared to traditional stainless-steel systems. It has been widely adopted in the biopharmaceutical field for various processes ranging from cell culture to drug formulation, including vaccines, antibodies, gene therapies, and cell therapies.

The Masterfilter Single-Use Systems and components are manufactured following the ISO 9001:2015 quality management system and adhere to GMP requirements. With 11 ISO 7 and ISO 8 production lines and one fully ISO 4.8 classified line, we can offer convenient and efficient single-use solutions that meet regulatory standards for biopharmaceutical and other industries.

We offer single-use systems with a wide range of standard and customized components that meet the customer requirements.

Features:

- Highest quality standards

- Short delivery times

- Experienced technical support

- Optimized production cost

Innovative Topene™ Blown Film for Bags

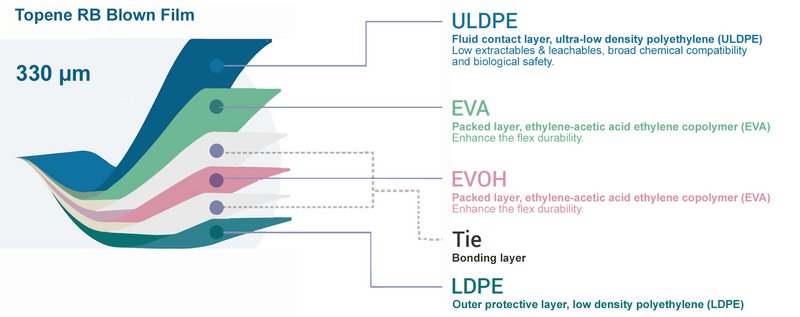

The innovative Topene™ RB blown film designed for biological processes is composed of ULDPE (ultra-low-density polyethylene), EVA (ethylene-acetic acid ethylene copolymer), EVOH (ethylene-vinyl alcohol copolymer) and LDPE (low density polyethylene). The ULDPE layer with low extractability, low precipitation, good chemical compatibility and biological safety is used as the liquid contact layer. The EVA layer has good resistance to flexural cracking and the EVOH layer minimizes gas diffusion of the film. The outer LDPE layer provides strong puncture resistance, strength and excellent thermal stability.

The Topene™ RB film has an ultra clean inner surface, good environmental stress resistance, tear resistance, rubbing resistance, tensile resistance, chemical stability and biological safety.

Features

- Superior mechanical strength

- Excellent flex durability

- Low extractables and leachables

- Superior cleanliness

3D Mixing Bags

The Lifecube™ 3D Single-Use Mixing Bags offer ultra-cleanliness, various sizes, pre-sterilization, ease of use, and more. These Single-Use Mixing Bags are made of multi-layer co-extruded film, feature good physical and chemical properties and extremely low gas permeability. They are suitable for a wide range of mixing steps in upstream and downstream processes.

Features:

- From 100 l to 3,000 l

- Customized bags

- Impellers

- Tubing

- Powder and Electrode ports

- Thermal electrode sleeve

- Sampling connectors

3D Liquid Storage Bags

Masterfilter offers Lifecube™ 3D Single-Use Liquid Storage Bags ranging from 50 l to 3,000 l for the biopharmaceutical industry. Our single-use storage bags are constructed of a 11-layer Topene™ RB film, with ULDPE as the fluid contact material and EVOH as the gas barrier layer. The outer protective LDPE layer is to optimize overall toughness of the bag. The single-use static bags are produced in ISO Class 7 cleanroom that is ISO 9001 compliant.

Features:

- From 50 l to 3,000 l

- Capsule and vent filters

- Powder ports

- Inlet and outlet connections

- Sampling connectors

- Customized bags

2D Liquid Storage Bags

Masterfilter offers Lifecube™ 2D Single-Use Storage Bags ranging from 1 l to 50 l for the biopharmaceutical industry. Our single-use liquid storage bags are constructed of a 11-layer Topene™ RB film, with ULDPE as the fluid contact material and EVOH as the gas barrier layer. The outer protective LDPE layer is to optimize overall toughness of the bag. The single-use liquid storage bags are produced in a Class 7 cleanroom that is ISO 9001 compliant.

Features:

- From 1 l to 50 l

- Capsule and vent filters

- Inlet and outlet connections

- Sampling connectors

- Customized bags

Aseptic Sampling Bags

Masterfilter provides a completed solutions of sterile sampling solutions for collection and storage of small volume samples. The Lifecube™ Aseptic Sampling Bags are available from 5 ml to 1000 ml and constructed of a 11-layer Topene™ RB film, with ULDPE as the fluid contact material and EVOH as the gas barrier layer. The outer protective LDPE layer is to optimize overall toughness of the bag. The single-use liquid storage bags are produced in ISO Class 7 cleanroom that is ISO 9001 compliant.

Features:

- From 5 ml to 1000 ml

- Bag ports

- Inlet and outlet tubing

- Connectors

- Customized bags

Filter Assemblies

The Lifecube™ Single-Use Filter Assemblies are used for interconnection of different unit operations in a wide range of applications. With our filter assemblies, you can easily connect multiple containers, vessels and process lines in one system, minimizing the risk of cross-contamination, saving time and reducing costs.

Features:

- Connectors and tubing assembly

- Double-layer packaging, sterilized by 25-45 kGy gamma irradiation

- Non-sterile packaging, autoclavable

- Customized assemblies

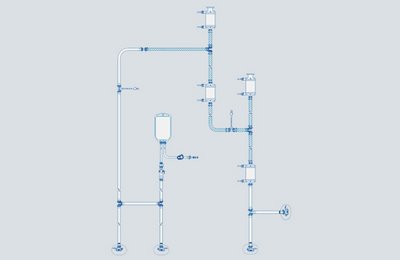

PUPSIT Assemblies

PUPSIT determines the integrity of the sterilizing-grade filter and assembly. PUPSIT is performed to help ensure that the filter has not been damaged during shipping, installation, and sterilization prior to use.

A damaged filter could result in a non-sterile product, which can ultimately affect drug safety. Masterfilter offers a range of pre-designed and pre-sterile PUPSIT Assemblies which are available in a wide variety of configurations.

Features:

- Full line of single-use products including sterilizing-grade filters, storage bags, tubing, aseptic connectors, fittings, pressure gauge, in-line pressure sensors and monitor

- Pre-designed and self-produced assemblies

- Supporting documents, including validation guide, extractable data, system design guide, user manual, application data, etc.

- Customized assemblies

Aseptic Connectors and Disconnectors

Aseptic Connections and Disconnectors are a crucial part of single-use biomanufacturing, which involves various manual connections to keep the fluid path closed throughout the process steps. Masterfilter offers a range of connection products that simplify, enhance flexibility and accelerate operations. These products are designed to ensure reliable performance, and regular maintenance contributes to their consistency.

Features:

- Genderless structure makes the connection more flexible

- Broad chemical compatibility

- Easy to use, three steps connection process

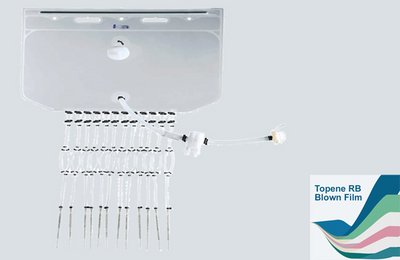

Final Filling Assemblies

Masterfilter Single-Use Final Filling Assemblies is a pre-assembled, pre-sterilized aseptic transfer production unit, including liquid storage bags, sterile filtration, single-use filling bags, filling tubing, and filling needles. Single-use filling assemblies are designed for the aseptic processing and transfer of biopharmaceutical fluids. They represent a critical advancement in modern drug manufacturing, replacing traditional stainless-steel vessels to enhance efficiency, safety, and flexibility.

Features:

- Innovative Topene™ RB blown film, reducing the contamination of particles

- Sterilized by 25-45 kGy gamma irradiation

- Designed with boat ports for ultra-low residual liquid

- Validation services are available for extractables and leachables, chemical compatibility

- Customized assemblies

System Integrity Tester

The Certitest™ System Integrity Tester ensures an accurate filter integrity testing with a reduction in test duration and complies entirely with the FDA 21 CFR Part 11 guidance on electronic records. Features as automation and network integration will save time and effort. Designed to be used in cleanroom environment, the Certitest™ has been developed and validated in accordance with the current GAMP guidelines. The Integrity tester includes the required controls and other features for operation in a 21 CFR Part 11 compliant environment. Data integrity controls, electronic records and signatures are available to support quality risk analysis.

Features:

- Integrity testing of single-use bags before or after use

- Supports custom pressure parameters within 300 mbar

- Two-stage inflation control, free combination of fast charging and fine-tuning

- Supports custom stabilization time and testing tests, and flexibly adapt to various testing scenarios

- Equipped with high-precision sensors, real-time display of pressure drop curve

- Confirmation when to start and stop the test, safe and controllable test operation

Media Bottle Assemblies

The Masterfilter Lifecube™ Single-Use Media Bottles meet the needs of liquid storage, transfer, sampling, package, and freezing in most bioprocess. The bottles are equipped with a high-strength threaded design to avoid the risk of leakage during transfer and storage.

Features:

- Bottle volumes from 30 ml to 1,000 ml

- Tubing

- Caps

- Connectors

- Vent filter

- Sampling

- Customized assemblies

Supporting Container

The Masterfilter Supporting Containers ensure secure and efficient storage, process and transport of bulk liquids and bioprocess liquids, meeting the highest industry standards. Designed for flexibility and reliability, they support the operations from storage, process and transport. Our range of supporting container are available in stainless steel and engineered plastic.

Features:

- Volumes from 50 l to 3,000 l

- Transport frame or wheels

- Loading flaps or swing doors

- Close or open hose compartment

- Top-drain or bottom-drain

- Hygienic design

- Customized solutions

Clean-Pass Wall-through System

The Masterfilter Clean-Pass Wall-through System is a solution designed for sterile fluid transfer within cleanrooms, whether at the same or different cleanliness class. This system features a novel design that utilizes stainless steel channels with disposable consumables to achieve aseptic transfer of single or multiple fluids, eliminating the risks of breakage or leakage associated with traditional physical transfer methods such as bags or containers.

Features:

- Eliminates the need to clean and validate

- Controllable transfer process

- Application safety

- Innovative design

- Suitable for various wall thicknesses

- Clean connection ports

- Innovative wall installation method